Web portal for buildingrelated information with a "whole building" focus provided by the National Institute of Building Sciences. Areas include Design Guidance ...

SGS MINERALS SERVICES – SGS T3 1001 3 HYDROMETALLURGY Working with the lithium concentrate, SGS'' team uses a standardized flowsheet to produce high grade .

Choosing the best hand grain mill is not as hard as you think, if you follow a few basic guidelines listed here.

The Woodcut MillDrill™ was designed to make the production of pepper grinders, that utilise the CrushGrind® mechanism, easier and quicker. However, it is a ...

Manufacturer of Wood Chipper MultiUtility Wood Chipper and Shredder, Heavy Duty Wood Chipper RJKHDWC15/20, Heavy Duty Wood Chipper RJKHDWC30 and .

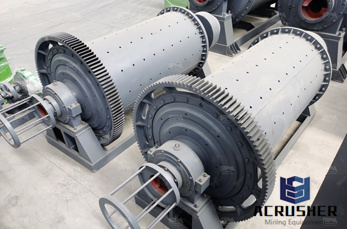

Wet Process Grinding Ball Mill, Wet Processing Ball Mill For Ore Processing Plant, Air Swept Dolomite Ball Mill

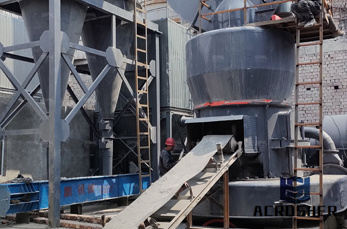

How is cement manufactured? Learn cement manufacturing process thoroughly.

Open the lid to your Ball Mill and add the following: 150 grams of Potassium Nitrate, 30 grams of Charcoal Powder, and 20 grams of Sulfur ( if your lead balls are not ...

Cement Kiln Process Specialist, expert trouble shooter for process problems with cement kilns.

New York importer, distributor and fabricator of natural stone products and ceramic tiles.

The use of ball mills for wet grinding of various materials is a very common and efficient process. Ball mills are used to grind raw materials, ores and

The process of reducing the particle sizes of both cocoa solids and sugar crystals in finished chocolate. The goal is somewhere in the range of 1525 microns.

During the design and production of our mills, we monitor every single detail – because often a small alteration is enough to make the grinding process even more ...

The ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silicates, refractory ...

Wet grinding mill,Pebble and ball wet grinding mills for sale . Double equipment manufactures a complete line of ball mills for every wet or dry grinding process ...

Sep 17, 2013· This video provides an overview of how to perform Critical Path Method (CPM) to find the Critical Path and Float using a ...

The ground materials are discharged through the discharging board thus the grinding process ... we use the wet type ball mill ... ball mill machine or ball grinding ...

Jan 30, 2012· and the heat generation in the process of dry grinding . In wet Grinding process, ... This should apply to ball mill grinding as well as ... Combination Dryer Grinder;

Grinding is the second step of mineral processing and the last stage of the comminution process. ... in use in wetgrinding mills. ... a ball mill in a grinding ...

An important advantage of the wet process is that there is no problem with ... In ball mills sometimes a grinding chamber with lifting blades and without grinding media

Ball Screws. Ball screws are very similar to ball bearings in that they generally use either chrome steel or type 440C hard stainless steel. A peculiarity of ball ...

Ball Milling Process Introduction: The ball mill is the key milling machine ... building materials and chemical industry can be divided into dry and wet two grinding ...

On Sep 1, 1996 C. Frances (and others) published: Analysis of Fine Wet Grinding in a Batch Ball Mill

Autogenous mills, semiautogenous mills and ball mills for wet grinding. A company of Polysius ... The resulting global know how of process and plant technology,

WhatsApp)

WhatsApp)