Chapter 7. Tubular Ball Mills Scribd. mill power in kW, a factor of the mill ... Thus the rupture of particles in a tumbling mill is a complicated function of the ...

1. Introduction. The power draw of a tumbling mill is known to be an important measure in determining its efficiency. Many models have been derived to predict the ...

critical speed of tumbling mill . ... The power drawn by a tumbling mill depends on the dynamics of the charge motion. » Get Quote. Charge Dynamics in Tumbling Mills.

85PREDICTION OF MILL STRUCTURE BEHAVIOUR IN A TUMBLING MILL Pär Jonsén 1, Bertil I. Pålsson 2, Kent Tano 3, Andreas Berggren 4

Mill power Usually, plant operators use mill power readings as an indicator of ball filling degree and, often, ... tumbling mills In 1988, Professor Moys, ...

Thus it will be apparent that a material saving is accomplished in the power required to project the abrasive into the drum and the power ... In a tumbling mill, ...

motion of the media in a tumbling mill are shown in The critical speed of the mill, ... Explain the role of critical speed and power draw in design and process control.

SINGHASINI Manufacturer of Ball / Tumbling Mill consists of a cylindrical shell which slowly turns about a horizontal axis is filled about half its volume with a ...

Scale Up in Sizing for Grinding Mills. Scaleup criterion is the net specific power consumption, the power consumed by the mill rotor itself minus all mechanical ...

The effect of ball size distribution on power draw, charge motion and breakage mechanism of tumbling ball mill by discrete element method (DEM) simulation

A ball mill is a type of grinder used to grind and blend ... but it was not until the industrial revolution and the invention of steam power that an effective ball ...

This review looks at the basic concepts of grinding mills ... The calculated power requirement is adjusted by utilizing ... Tumbling mills: In this mill, ...

Dec 07, 2011· Tumbling mill . European ... Whilst a factor of the power requirement for the mill is related to its crosssectional diameter, ...

dynamics tumbling mill in usa – Grinding Mill China tumbling mills – Mining Solution Analysis of power draw in tumbling mill, ... Tumbling mill | Article about ...

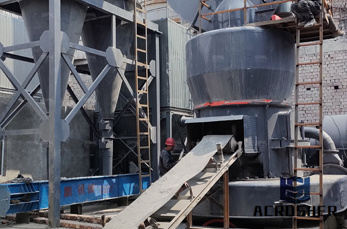

The tumbling mill is an efficient tool for grinding many materials into fine powder, which is widely used in building material, chemical industry, etc. such as cement ...

Video embedded· How to optimize a 6 pound ball mill to safely and ... Quick Easy Black Powder Ball Mill ... you''ll find that your black powder either does not have enough power.

Characterization of laboratoryscale tumbling mills Steiner ... The difference between the power draw while tumbling the mill charge and the idling

Find equipment suppliers of MILL, Tumbling serving the ceramic, glass, brick, decorating and related markets in the ceramic manfuacturing industry.

tumbling mill double wave liner. Head office address. ... Sep 20, 2008 ... ability to predict load motion and power draw by tumbling mills as affected by ...

The flexible rubber lifter and the lining in a tumbling mill are modelled with the finite element method (FEM) ... energy loss spectra and power consumption.

It is evident that mill power is a function of the height at which the media is lifted and the ... AMIT 135: Lesson 1 ... AMIT 135: Lesson 7 Ball Mills ...

measuring the efficiency of the tumbling mill as a function of lifter configurations and operating parameters by ... mill power draw ...

A public Database of tumbling mill ... Some examples of powerbased model specific energy predictions will be compared to published mill surveys to observe how ...

The discrete element method models the motion of charge in tumbling mills using the physics of individual collision between balls, rock particles, and mill shell.

WhatsApp)

WhatsApp)